Worker Accommodation

It is common in regions where large construction projects are taking place for worker accommodation buildings to be erected. These buildings are usually located near the main site and are demolished after the project is completed.

Worker accommodation buildings vary in style around the world. In the Middle East, they are typically multi-storeyed dormitory type buildings, while in Australia they are single-storied units. These buildings need to be quick to build and robust in nature due to the transient workforce that inhabit them. To be cost-effective, where possible, local cladding building materials are used. In the majority of cases, these buildings have a fixed lifespan that coincides with the construction project they are built for.

Steel frame is ideally suited to the production of these buildings because of the following factors:

- Quick and easy to assemble and erect

- Cost effective

- 100% recyclable

- The framed structure is self-supporting so can be clad with locally available materials

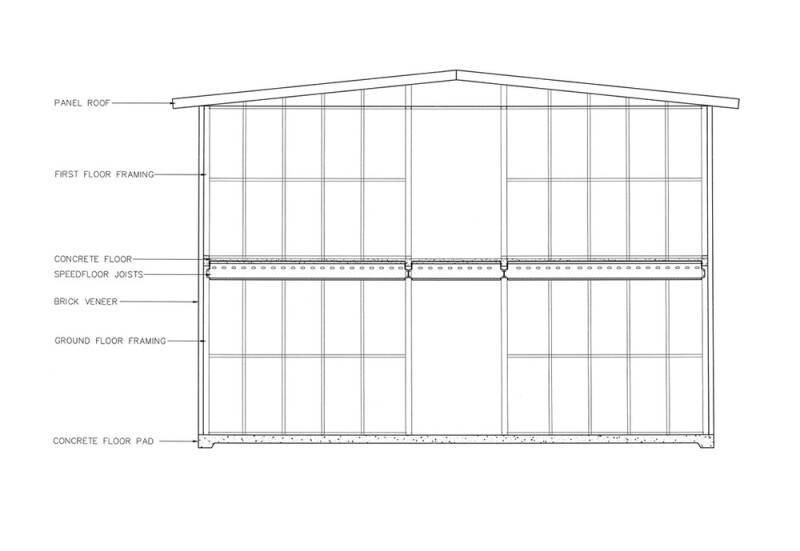

The buildings can be constructed from a single machine including all the walls, trusses and lattice floor joists. Alternatively, the building can be constructed using the Speedfloor concrete flooring system with the steel frame to build a more permanent structure.

Howick’s mobile factory is ideal for production on new sites in remote locations.

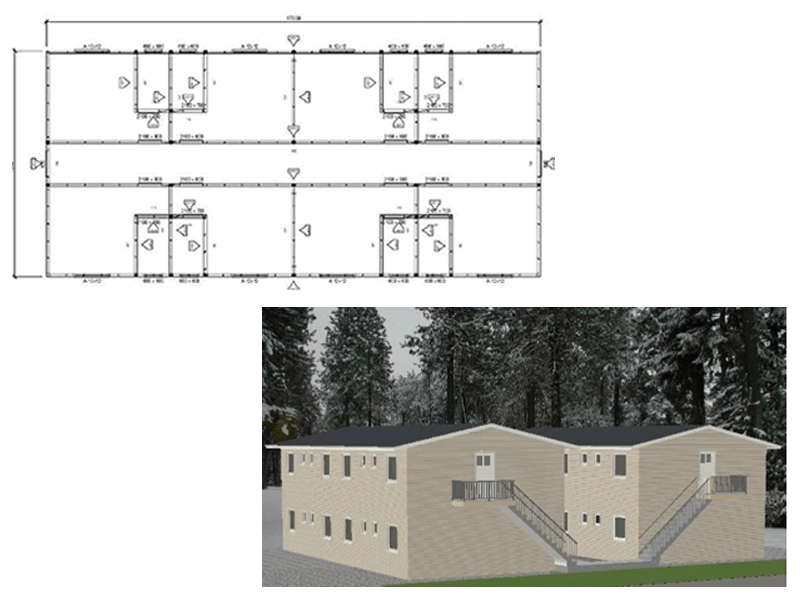

Sample of Two Identical Buildings

This sample of two identical buildings with steel frame and concrete floors is designed to fit all the structural elements of the building into a single 20’ shipping container. Each building has 16 rooms and bathrooms.

Once the frames have been erected, the concrete floors are poured and then the structure can be clad in the required materials. The advantages of this system include:

- More robust flooring system

- Better sound and fire performance

- Better building performance in seismic and cyclonic conditions

- More thermal mass allowing easier temperature regulation

- Deliverable to site in kit-set form

- Rapid construction

Sample of Two Identical Buildings