Innovation

Howick – An innovator since day one

Innovation is part of the Howick creation story. Since our foundation in 1978, in true Kiwi style we have applied creative thinking with engineering nous to solve challenging, technical problems. Coupled with a focus on continuous improvement, it is a mindset that has helped Howick become a leader in light gauge steel framing automation with a global reputation for innovation, quality and steely reliability.

Howick started out engineering one-off machines to do everything from shaping copper piping for refrigerators, to making ice cream, and coil paint coating lines. Each machine was a custom-made solution. Then Howick began specialising in light steel roll-forming machines for construction. This enabled us to build systems and tooling for everything from creating the components for garden sheds right up to framing multi-level buildings up to 12 storeys.

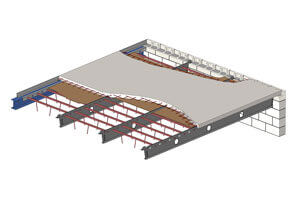

Howick’s belief in innovation was solidified in 2003 when the business opened a special research and development facility for roll-forming services. Howick has hosted the International Innovation Conference on two occasions. ‘Firsts’ include the development of the SPEEDFLOOR® machine for roll-forming steel flooring components, the capability to roll-form load bearing components in light steel for high-rise buildings, and in 2020 the launch of the X-TENDA™ 3600, a new machine that manufactures extendable, telescopic panels for interior and infill framing (as well as standard frame and truss).

Investing in R&D

Research and development capabilities were improved in 2016 with the installation of new CNC manufacturing equipment and followed up in 2017 with the arrival of a 200kN universal testing machine to increase R&D capacity and product testing. The company has received several awards over the years recognising its innovative approach, including the ExportNZ Best Medium Business Award, the Westpac Award for Excellence in Exporting and the Metal Industry Innovation Award. At Howick, R&D is not just a department, it is at the heart of everything we do.

Give it a go attitude fuels innovative spirit

Innovation is an attitude that persists throughout the business. In the words of Nick Coubray, CEO “Anyone can come up with an idea for a different way of doing something. And if we think it will fly, because we manufacture everything in-house as far as machine designs, control and hardware is concerned, it is relatively easy to give it a go. We can try stuff, and if it doesn’t work, nothing ventured, nothing gained!”

The results of innovation: X-CALIBR™ a new leader in portal framing

In 2022 Howick’s ‘give it a go’ attitude paid dividends in the form of a groundbreaking innovation, X-CALIBR™. This new technology was developed in partnership with our sister company Central Steel Framing to replace traditional heavy steel construction methods.

No need to use traditional heavy hot rolled steel, which is slow, expensive and time consuming to manufacture - now contractors have a faster, lighter prefabricated option, that eliminates the need for drilling, cutting, welding, and measuring onsite. X-CALIBR™ cuts material and labour costs, whilst dramatically reducing onsite assembly time.

Innovation is about looking out for tomorrow

This focus on innovation and the development of products like X-CALIBR™ is about looking at how Howick can add the most value to the construction sector in the future. Again, in Nick’s words, “You know that today is important, but tomorrow is more important if we look at it from the point of view of how we leave the world in a better state than we are currently in. We are a small part of solving the global housing shortage and hopefully we can contribute to that and help some others along the journey as well.”

The most important part of our R&D? Ensuring quality

Another way that Howick helps make tomorrow a little better is by ensuring that every single component that comes out of our factory is rigorously tested. After all, innovation is nothing without quality.

We work with the University of Auckland and the University of Waikato, as well as using our own testing facilities to leave no stone unturned.

Every product that leaves our hands has undergone a number of tests, including advanced Finite Element Method (FEM) analysis and complex computer simulations. These tests allow us to constantly refine our products to ensure that our customers receive the best in reliability, safety, and performance.

View some photos from our recent tests:

2024

TAMPA 2024 cements STEEL HORIZONS as an event not to be missed on the global construction calendar.

2021

Howick is recognised by TIN (Technology Investment Network) as one of the top 10 Supreme Scale-Ups, based on revenue growth in the past year.

2020

Howick launches its best and most forward-thinking product yet, the X-TENDA 3600™, which promises to transform interior framing

2019

Howick wins ExportNZ Best Medium Business Award, recognising Howick’s role in the automation and future of the global building industry.

2017

Installed 200kN universal testing machine to increase R&D capabilities and product testing

2016

Installed new CNC manufacturing equipment to meet production and R&D growth

2015

First Howick framing on-site manufacture trailer

2015

Introduction of the FRAMA machine Convertible Series

2013

Introduction of the FRAMA range of framing machines

2012

Howick secures Speedfloor partnership with major Indian manufacturer

2012

Howick holds second International Innovation Conference

2011

Howick receives Westpac Award for Excellence in Exporting

2011

Howick recognised by TIN100 as one of NZ’s Top 10 Hot Emerging Companies

2011

Howick receives NZ Metal Industry Innovation Award

2010

Howick holds first International Innovation Conference

2009

Howick designs and builds H400 truss machine

2008

Designed and built H600 floor joist machine

2007

Howick opens sales and support office in the United Kingdom

2006

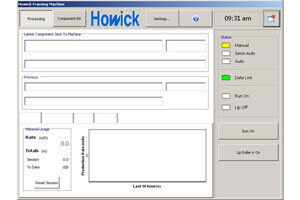

Introduction of Windows based open language controller (CSV)

2004

First mobile factory operates in Hawaii

2003

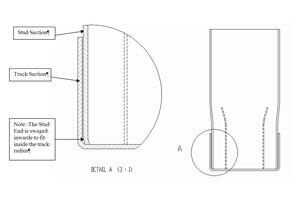

Developed end-bearing detail that opened the opportunity for high rise LGSF buildings

2003

Developed innovative window well corrugator for Canada that formed and processed the final product

2003

Howick opens new research and development facility for rollfoming services

2002

Launched second generation H500 model steel framing machine

2000

Launched second generation H300 model steel framing machine

1999

Designed and built Waterjet Beamline

1998

Designed and built first Speedfloor machine

1997

Designed and built compact steel framing machine

1996

Designed and built dual raft steel framing machine

1995

Developed automated garage door production line allowing for custom door size manufacture

1994

Designed and built 30 seater bike for FADE

1993

Built a 12 stand custom multi-section Rollformer 1993

1987

Produced a refrigeration tube bender machine for Fisher & Paykel

1986

Extended Howick factory

1978

Keith and Bruce Coubray start Howick Engineering