Custom Built Roll-Forming Machines

The team at Howick has a long history of developing custom one-off machines and systems as well as product development. Spending time to understand our customers’ product requirements allows us to develop innovative solutions, going beyond offering more than a machine to produce a product.

If you need a custom machine, please contact Howick head office to discuss your requirements and details.

Please see examples of our custom machinery below.

Examples of custom machinery:

Gallagher Kiwitar post former

Howick was commissioned to develop a new rollformer to fit within the existing production line. Gallagher’s Kiwitar fence post is now used around the globe.

Examples of custom machinery:

Staplelock fence post

The staplelock system consists of a rollformed section with a pressed spike for interstation into the ground. It also has a serrated edge and a custom designed staple.

Window well former

Asked to quote for producing a corrugated section for a Canadian company, we examined the end use and proposed fitting an integrated bender unit to the corrugator, making production line for a fully processed window well production line. This lessened production from eight processes to one and significantly reduced manufacturing costs and time.

Take a look at the machine in action.

Custom press and tooling tool

This compact press was designed for multiple uses including:

- Custom washer press

- Facade system mounting plate manufacture and pressed connection attachment

- Pipe compression testing

Fence panel rollformer

Custom corrugate section for the production of fences.

Brick tie machine

We developed this to produce cut to length brick ties to be attached to the building frames instead of purchasing and processing fixed length bought in bulk, thus reducing waste and increasing production efficiencies.

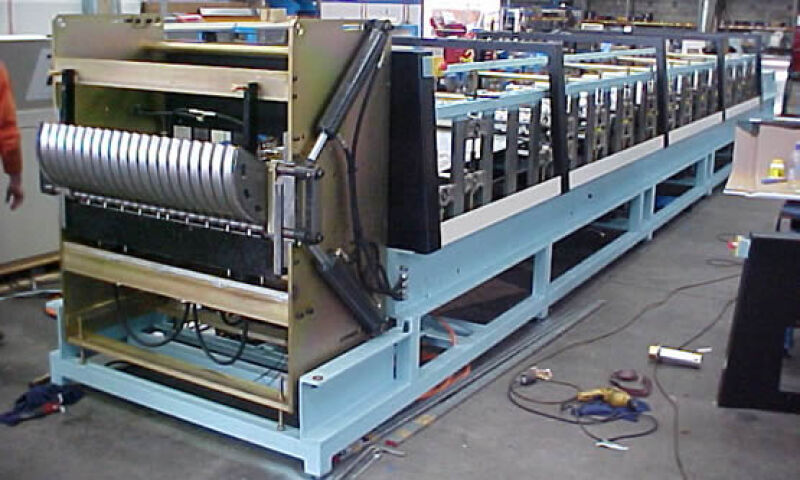

Double deck corrugator

The double deck corrugator was a solution to the problem of limited space in the customers production facility. Two sections produced in a two level over and under configuration gives the opportunity to produce different sections from a single machine.

Pallet racking system

This was commissioned to develop a pallet racking system production line, including posts and welded beam section. This system has a unique system punching arrangement allowing it to be connected to a range of other systems without adapters.

Waterjet beamline

Developed to replace the manual process of producing hot rolled steel structural components, the waterjet beamline can process a range of different sections without heat and allowing accurate and fast production. Take a look at the machine in action.

Cable ladder rollformer

This machine was developed to produce multiple different cable ladder sections.

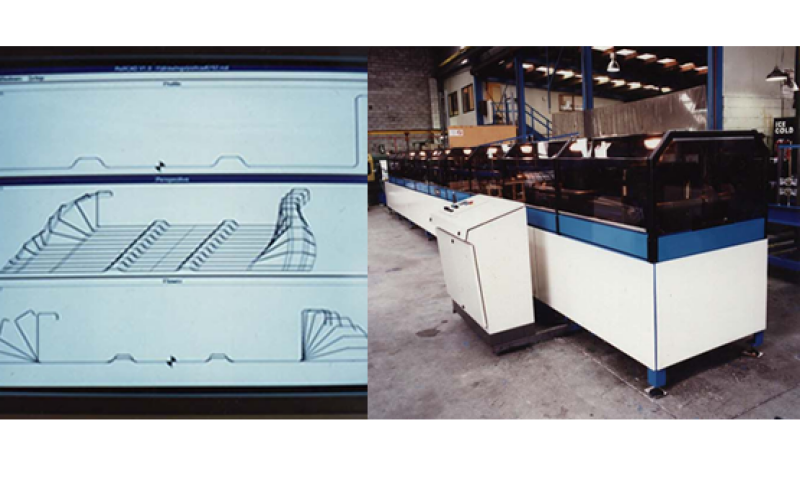

Paint chart machine

This machine was developed to apply colour samples to paint charts at high speed.

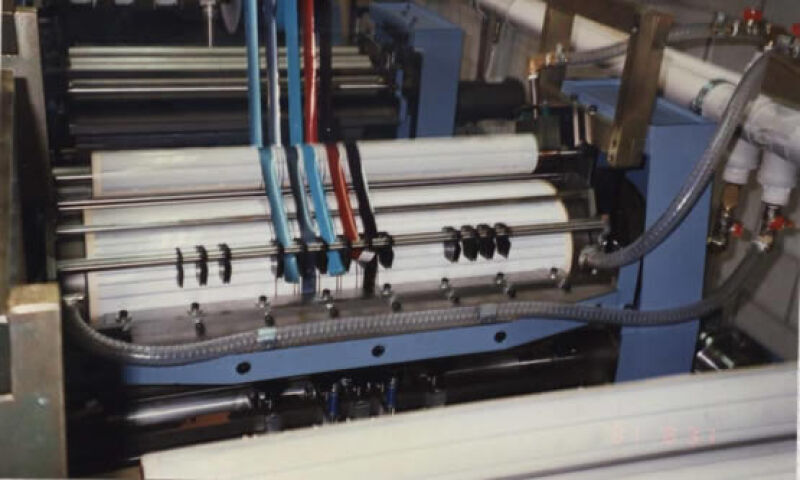

Coil laminator

This unit is used to apply film to protect Colorsteel for rollformers as an unpowered unit or for folding and sheeting lines as a driven unit with a built-in slitter and length control.

Trim deck rollformer

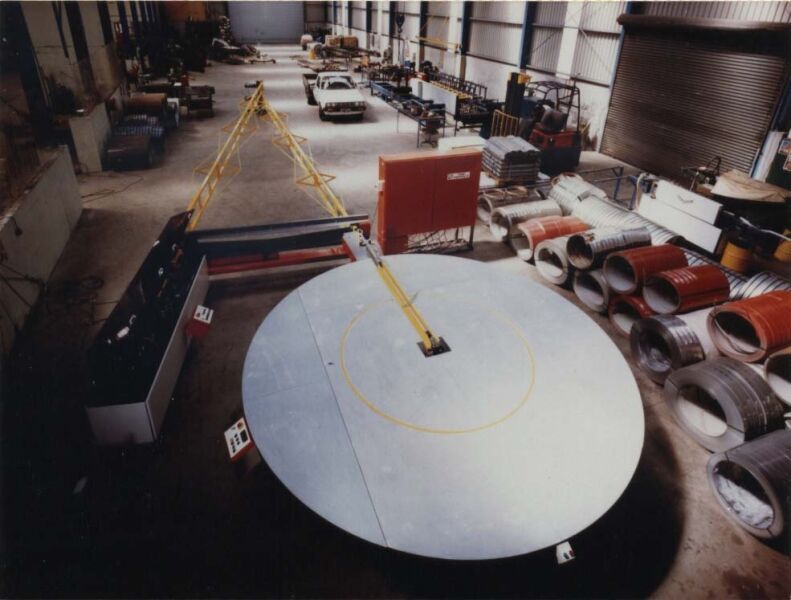

Speedfloor composite flooring system

Speedfloor is a unique beam used for composite concrete flooring systems. For more information visit: www.speedfloor.co.nz

Refrigeration Tube Bender for Fisher and Paykel.

This machine bent sets of tubing for the refridgeration production line for Just In Time production.