FRAMA™ 7600

Multi-Purpose System: Frames, Trusses, Panels (75 to 200mm / 3" to 8" Sections)

- Gauge Range

-

- Production Speed

-

- Dimensions L x W x H

-

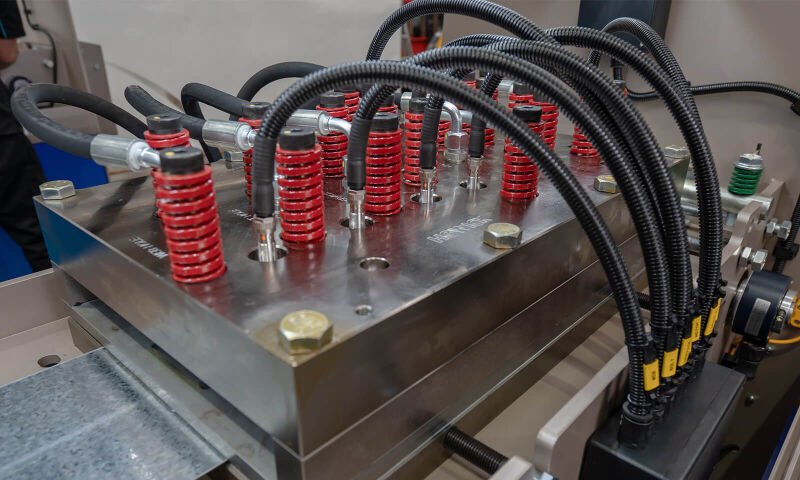

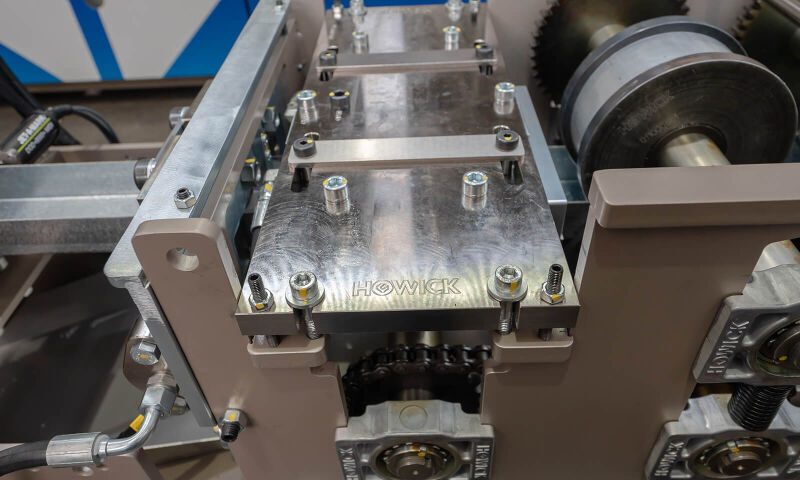

For ultimate flexibility, the Howick FRAMA™ 7600 is a convertible profile frame and truss system. With our unique end-bearing stud detail for true load-bearing frames, plus our swage and dimple details for smooth intersections, this machine is convertible to up to 5 different framing sizes for a range of construction needs.

With the FRAMA™ 7600 in your armoury, you are equipped to produce a single profile size and add additional tooling for alternative profile options as needed.

Our convertible design overcomes many of the traditional compromises that go with making multiple sections with adjustable tooling. It is compact too, which reduces wastage and improves accuracy. As well as the potential to add tooling for additional widths, if your production requirements increase you can simply add another base unit and use your existing tooling for multiple line runs. It offers a gauge range of 0.95 to 1.55 (20 to 16 gauge), and a production speed of up to 800m/2624ft per hour.

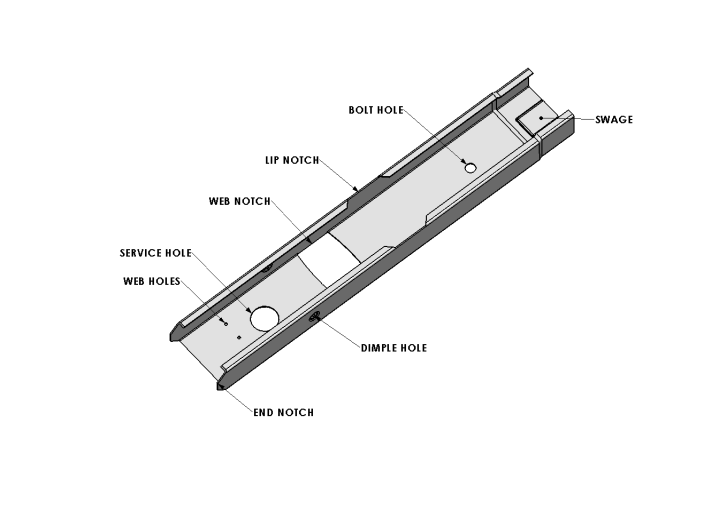

The FRAMA™ 7600 includes Howick's unique end-bearing stud detail for true load-bearing frames and Howick's swage and dimple details for smooth intersections. The FRAMA™ 7600 machine is convertible up to 5 framing sizes.

With the unique design of the FRAMA™ 7600 machine you can produce a single profile size and add additional tooling sets for remaining profile options as/or when needed, without the cost and complication of a multiple profile roll-former.

Howick's convertible machine design overcomes many of the compromises that go with making multiple sections with adjustable tooling. The compact design of FRAMA™ 7600 means less material wastage when changing section width, and higher product accuracy. Convertible design ethos means you can add tooling for additional widths as required. If your production requirements increase, you can buy another base unit and use your existing tooling to run multiple profiles from one machine.

The machine operation is taken from Howick's proven reliable design concepts to minimise down time and maximise production.

| FRAMA™ 7600 | ||

| Dimensions L X W X H | 4.95m x 0.90m x 1.40m | 16' 3" x 2' 10.5" x 4' 7" |

| Weight | 5500kg | 12125lb |

| Drive Motor Power | 7.5kW | 10hp |

| Hydraulic Power | 5.5kW | 7.4hp |

| Hydraulic Tank | 60L | 15.85gal |

| Hydraulic Cooler | Optional | |

| Forming Stages | 13 | |

| Line Speed | 24m/min | 80'/min |

| Production Speed | up to 800m/hr* | up to 2624'/hr* |

| Touch Screen | Panel PC (Windows 10) | |

| Machine Control | FRAMA Machine Control | |

| Machine Input Files | CSV | |

| Tooling | Standard Tools | |

| Truss End Tool, Service Hole, Web Hole, Bolt Hole, Lip Notch, Web Notch, Dimple, Swage, End Bearing Cut-off | ||

| Component Marking | Dual Head Inkjet Printer | |

| Decoiler | ||

| 3.0T Decoiler | 6600lb Decoiler | |

| Dimensions L X W X H | 1.35m x 1.0m x 1.45m | 4.5' x 3.3' x 4.9' |

| Weight | 700kg | 1550lb |

| Drive Motor | 4.0kW | 5.4hp |

| Jaws | 3 Jaw Self Centring | |

| Jaw Expansion | Hydraulic | |

| Jaw Expansion Range | 480mm - 520mm | 1' 7'' - 1' 8 1/2'' |

| Speed Control | Dancer Arm with Inclinometer | |

| Auto Pause at Coil End | ||

| Max Coil Weight | 3000kg | 6600lb |

| Mac Coil Width | 400mm | 1' 3 3/4'' |

| Mac Coil OD | 1500mm | 4' 11'' |

| Nominal Bore | 508mm | 1'8'' |

| Safety | CE, UL, Cat 3 Compliant | |

| Guarding | Fully Guarded Chains & Electrical Controls | |

| Howick Ltd Reserve the right to update the machine specification without notice *Production Speed will vary due to component complexity. |

||

STANDARD METRIC SIZES

|

Web Size |

75mm | 89mm | 100mm | 150mm | 200mm |

| Flange Height | 45mm | 45mm | 45mm | 45mm | 45mm |

| Lip Width | 10mm | 10mm | 10mm | 12.7mm | 12.7mm |

| Nominal Coil Width | 171mm | 185mm | 196mm | 251mm | 301mm |

| Web Hole | Triple 3.5mm | Triple 3.5mm | Triple 3.5mm | Triple 3.5mm | Triple 3.5mm |

| Service Hole | 34.1mm | 34.1mm | 34.1mm | 34.1mm | 34.1mm |

| Bolt Hole | 3.5mm | 3.5mm | 3.5mm | 3.5mm | 3.5mm |

| Dimple Hole Size | 3.5mm | 3.5mm | 3.5mm | 3.5mm | 3.5mm |

| End Truss Miter Tool | 45° Cut Std | 45° Cut Std | 45° Cut Std | 45° Cut Std | 45° Cut Std |

STANDARD IMPERIAL SIZES

|

Web Size |

3'' | 3.5'' | 4'' | 6'' | 8'' |

| Flange Height | 1 5/8' | 1 5/8'' | 1 5/8'' | 1 5/8'' | 1 5/8'' |

| Lip Size | 3/8'' | 1/2'' | 1/2'' | 5/8'' | 5/8'' |

| Nominal Coil Width | 0.56' | 0.61' | 0.64' | 0.82' | 0.99' |

| Web Hole | 1/2'' | 1/2'' | 1/2'' | 1/2'' | 1/2'' |

| Service Hole | Triple 1/8" | Triple 1/8" | Triple 1/8" | Triple 1/8" | Triple 1/8" |

| Bolt Hole | 1 11/32'' | 1 11/32'' | 1 11/32'' | 1 11/32'' | 1 11/32'' |

| Dimple Hole Size | 1/8" | 1/8" | 1/8" | 1/8" | 1/8" |

| End Truss Miter Tool | 45° Cut Std | 45° Cut Std | 45° Cut Std | 45° Cut Std | 45° Cut Std |