Why Howick

Engineering that gives you an edge

Howick builds high precision light gauge steel roll-forming machines that help you deliver better buildings, faster. An innovator since day one, we have been solving technical engineering challenges and delivering creative solutions since 1978. It is a mindset that has helped Howick become a leader with a global reputation for innovation, quality and steely reliability.

This is the engineering advantage our customers rely on.

A family owned business with global reach

As a proudly family owned company, we design, build and rigorously test every machine in our Auckland facility. By using only components we manufacture ourselves or source locally, we maintain tight control over quality and performance. Our team brings deep technical expertise to building and supporting your equipment, and as a family business, we are committed to standing by our customers for the long haul.

Proven systems built for accuracy and speed

Our roll-forming machines turn coiled steel into accurate frames, panels, floors, walls and trusses for a full steel framing solution. Trusted in more than 80 countries, they deliver ±0.5mm accuracy, with open language control systems, no meterage fees and groundbreaking engineering features such as true load-bearing joints and telescopic framing. This gives you capability that scales with your work and lets you take on more complex, higher value jobs.

Enabling digital-to-physical workflows

Howick machines form a direct link between your digital model and physical fabrication. Build data flows from your CAD platform into precise, ready-to-assemble steel components with minimal manual handling. This reduces errors, speeds up production and gives you confidence that what you design is exactly what you deliver.

A partner helping lead the industry forward

Howick is more than a machine manufacturer; we are a voice helping to drive the industry forward. Our STEEL HORIZONS and SMART BUILD SPOTLIGHT series give you access to practical ideas, new approaches and valuable lessons from industry trailblazers. You will learn what has worked for those leading operators and pioneers already building smarter and faster with steel, and find plenty of inspiration for taking on new challenges.

Ready for housing, commercial and modular builds

Whether you are building housing, low-rise commercial spaces or modular pods, our systems help you cut time, lift quality and reduce waste. If you want to shift to light steel framing or take your current steel work further, we are ready to help. Let us talk

Team Howick

NZ and Global Sales

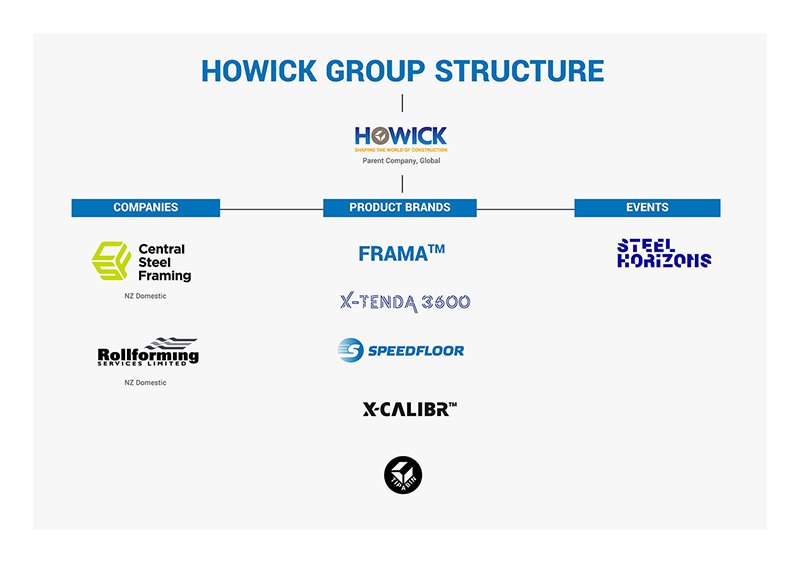

Howick Group Structure

Howick Group is a multi-faceted light-steel framing solutions business that spans several innovative companies, products, and even an international industry event.

Work with us

We are a successful family owned and operated business. As such, family values and a real can-do Kiwi ingenuity define our culture. Howick is helping to shape the future of construction globally. We are an internationally recognised, industry-leading company that is committed to education, training and developing opportunities for our team to expand and diversify their experience. If you see yourself as forward thinking, eager to learn and you want to be part of a growing game-changer, we’d love to hear from you.

Eco Statement

If we are to be part of the solution for a construction industry solving a global housing supply issue, it is fundamental that we take responsibility for sustainable framing manufacture. Our machines employ everything from energy efficient drive motors that surpass EFF1 requirements, to auto-off switches and EMC filters to minimise environmental impact. That is just the start. Sustainability for us is about a reduced overall carbon footprint, maximised recycling capability and optimized energy efficiency. That is better for the environment, and it is great for your bottom-line too.

Innovation

Innovation is part of the Howick creation story. Since our foundation in 1978, in true Kiwi style we have applied creative thinking with engineering nous to solve challenging, technical problems. Coupled with a focus on continuous improvement, it is a mindset that has helped Howick become a leader in light gauge steel framing automation with a global reputation for innovation, quality and steely reliability.